GORE® Anti-Static High Flex Cables for Semiconductor Production Equipment

Our next-generation cable technology is proven to prevent electrostatic buildup and reduce particle attraction for increased reliability and higher throughput in semiconductor and FPD equipment. An industry first, our anti-static high flex cables can be used in an ESD-sensitive environment without additional equipment or a complex grounding system.

Kontakt

United States

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Product Overview

REDUCE ESD-RELATED FAILURES & PRODUCT DAMAGE

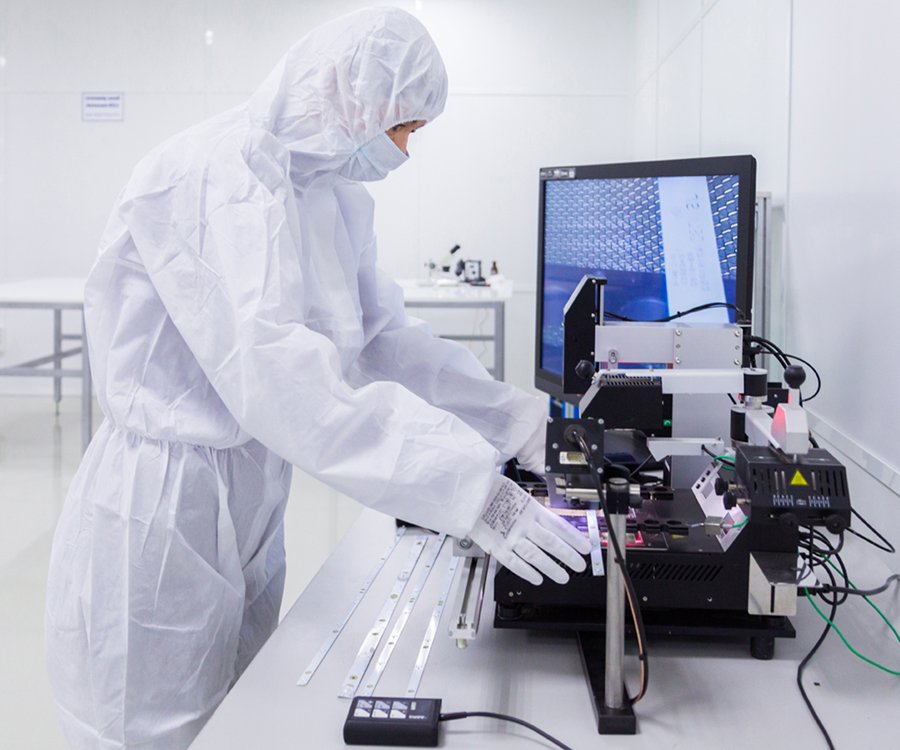

Evolving design/production technologies in semiconductor and flat panel display (FPD) equipment are making it possible for the industry to move toward higher-density designs. But these designs also make FPDs and integrated circuits (ICs) more susceptible to damage from electrostatic buildup. The electrostatic voltage that builds up over time attracts particles on the outer surface of a moving cleanroom cable system, causing uncontrolled particulation and reduced yield.

GORE Anti-Static High Flex Cables feature an expanded polytetrafluoroethylene (ePTFE) composite jacket material with a non-carbon-based dissipative treatment designed precisely for use only in electrostatic discharge (ESD) environments.

We offer two versions that help prevent triboelectric charge and voltage buildup for improved protection against ESD events. They reduce particle attraction to eliminate surface charge buildup, uncontrolled particulation, and possible discharges.

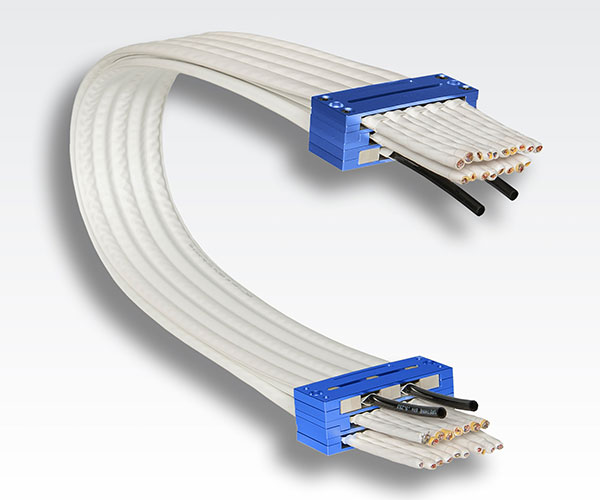

Our trackless cable consists of a flat jacket incorporating individual cores and a strength member that provides self-supporting rolling flex motion. And our flat cable incorporates individual laminated cores for a lighter and more flexible solution.

The first of its kind in the industry, our unique cable technology can be used in an ESD-sensitive environment without any additional effort to install it. These cables don’t require a complex ground system or extra equipment to perform either. They also eliminate the need for ionizers that are costly to calibrate and maintain.

Our anti-static high flex cables significantly reduce ESD-related failures and product damage for increased reliability and higher throughput in your high-flex machinery. As a bonus, they’re 100% compatible and can be easily retrofitted into our standard trackless and flat cables.

Applications

Proven to reduce ESD-related events, GORE Anti-Static High Flex Cables are used in a variety of semiconductor production equipment, including:

- electronic component packaging equipment

- advanced bonding equipment

- pick & place mounter equipment

- back-end manufacturing & inspection processes

- lens manufacturing equipment

- manufacturing equipment sensitive to ESD

Have high-flex equipment in an ESD-sensitive environment with challenging cable specs? Contact us today to talk about what we can do to meet them and how our product can help.

Features & Benefits

We’ve engineered GORE Anti-Static High Flex Cables with unique features that make them more durable in ESD-sensitive environments requiring high cleanliness levels, including:

- non-carbon-based, dissipative jacket material

- low-friction, non-particulating materials

- temperature-resistant materials

- chemically inert materials

Our proven, reliable cables provide manufacturers with many benefits that improve semiconductor and FPD equipment performance, like:

- prevent surface charge buildup and eliminate uncontrolled particulation

- significantly reduce ESD-related failures and product damage

- industry first to be used in an ESD-sensitive environment as a stand-alone system

- no complex grounding system or additional equipment needed

- eliminate the need for ionizers that are costly to calibrate and maintain

- increased reliability, higher throughput, fewer maintenance cycles and lower cost of ownership

- certified for ISO Class 1 cleanroom environments

- easy retrofit with standard trackless and flat cables

Technical Specs

These values demonstrate the electrical, mechanical and environmental performance of GORE Anti-Static High Flex Cables for semiconductor production equipment in an ESD-sensitive environment.

| Elec. / Mech. / Environ. Property | Value | |

|---|---|---|

Trackless Cable | Flat Cable | |

| Maximum Acceleration g (m/sec2) | 4.0 (40) | 4.0 (40) |

| Speed m/sec | 4.0 | 4.0 |

| Surface Resistance Ohms (ASTM-D257) 45% rH, 23°C | </= 2 x 109 | </= 2 x 109 |

| Typical Charge Decaya msec (DIN-EN 1149-5; 2008-04) 45 rH, 23°C | ≤ 4 | ≤ 4 |

| Voltage Buildupa V (PLFWI-2730 up to 1000 Cycles) | << 100 | << 100 |

| Operating Relative Humidity rH % | 45 + 15 | 45 + 15 |

| Jacket Materialb | Expanded PTFE Composite with Non-Carbon-Based Dissipative Treatment | Expanded PTFE Composite with Non-Carbon-Based Dissipative Treatment |

| Jacket Color | White | White |

| Core Types | Signal, Power, Fiber Optic, Pneumatics | Signal, Power, Fiber Optic, Pneumatics |

| Maximum Self-Supporting Stroke Lengthc mm (in) | 1500 (60) | 500 (20) |

| Overall Widthd mm (in) | Up to 105 (4.1) | Up to 300 (12) |

| Minimum Bend Radiusd mm (in) | 50 (2) | 50 (2) |

| Flex Life Cycles (BR. 50 mm up to 4G Accelerations) | > 10 million | > 20 million |

| Temperature Range °C | -40 to +80 | -40 to +80 |

| Cleanliness Classe (ISO14664-1 up to 1 Mio Flex Cycle) | 1 | 1 |

| Particulationf % (ISO14664-1 / VDI Guideline 2083) | < 0.1 | < 0.1 |

a. Results may vary under different conditions. Test method details available upon request.

b. Details of Gore’s patent available at patents.justia.com/patent/9534159.

c. Baseplate required.

d. Standard configuration only. MBR can vary with specific configurations.

e. Based on Anti-ESD Trackless Cable, GKT-FTFH-01-A, Serial Number 14111802. Qualification report available upon request.

f. Details of the Fraunhofer Institute’s study available at gore.com/particulation.

How to Customize or Buy

GORE Anti-Static High Flex Cables help reduce ESD-related failures and product damage in environments requiring high cleanliness levels. We offer standard or customized configurations with mounting clamps for semiconductor and FPD equipment.

Follow a few easy steps in our design guide to choose from the most common industry components and customize your own cable that meets your precise requirements. Once you submit your information, a Gore representative will review your requirements, contact you with a recommendation and provide a drawing.

If you need help designing an anti-static high flex cable to meet your specific semiconductor production equipment needs, contact us today.

Resources

White Paper: Cable Particulation Study for Cleanroom Environments

White Papers, 144.55 KB

Data Sheet: GORE® Anti-Static High Flex Cables For Semiconductor Production Equipment

Data Sheets, 150.89 KB

View all resources for Cables for Semiconductor Production Equipment

Aktuellste News

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Folge GORE® Anti-Static High Flex Cables for Semiconductor Production Equipment