GORE® Ultraclean Static Round Cables and Assemblies for Lithography

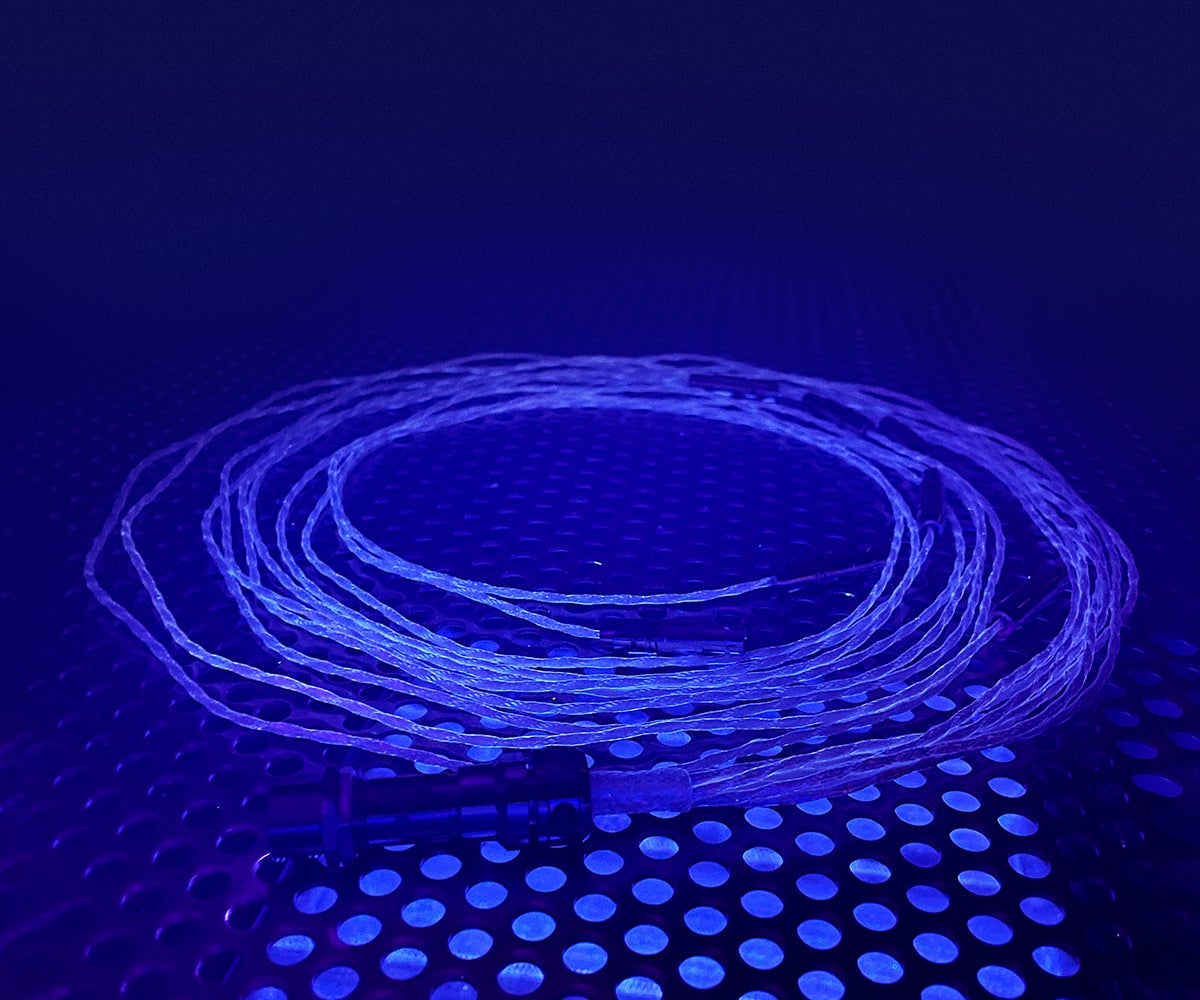

These Cleanliness Grade 1 cables are developed and validated to meet the semiconductor industry’s most rigorous EUV requirements for purity, reliability and signal integrity. Custom-engineered with ultra-high vacuum components, they’re proven to provide unmatched cleanliness, durability and performance.

Kontakt

United States

+1 800 356 4622

Europe

+49 9144 6010

China

+86 755 8359 8262

South Korea

+82 2 393 3411

Overview

GREATER CLEANLINESS & RELIABILITY

The growing demand for semiconductors — driven by 5G, the Cloud and AI — will only intensify as more devices and technologies are integrated into homes, workplaces and transportation systems. To meet this accelerating demand, fabs using EUV (extreme ultraviolet) and DUV (deep ultraviolet) lithography processes must increase their speeds and output without sacrificing purity or precision in the process.

Gore thinks ahead and grows with customer requirements. We continue optimizing our capabilities and cables for vacuum environments so we’ll be prepared to meet newer, more stringent standards for cable cleanliness, durability, flexibility and reliability.

The material properties and performance characteristics of GORE Ultraclean Static Round Cables and Assemblies align perfectly with these goals. They offer greater precision and cleanliness to support more extreme miniaturization and greater reliability to support demands for higher yield, quality and speed. Our cables can achieve higher data rates with greater signal integrity over longer distances, along with precise, reliable terminations.

BUILT FOR HIGH-VACUUM ENVIRONMENTS

We incorporate chemically inert, low-contamination and low-outgassing fluoropolymers, like ePTFE (expanded polytetrafluoroethylene), that provide unmatched cleanliness, durability and performance. And we can further trim outgassing levels to meet customer requirements.

Our material expertise and rigorous cleaning processes mean that each element of our finished cables — from raw materials to individual strands and final assemblies — delivers the cleanliness that high-purity lithography processing and high-vacuum applications demand.

This cleanroom static round cable design also has a tight bend radius for easy installation in tight spaces with precise, reliable terminations. They’re approved for use in the innermost parts of the most advanced EUV systems.

Applications

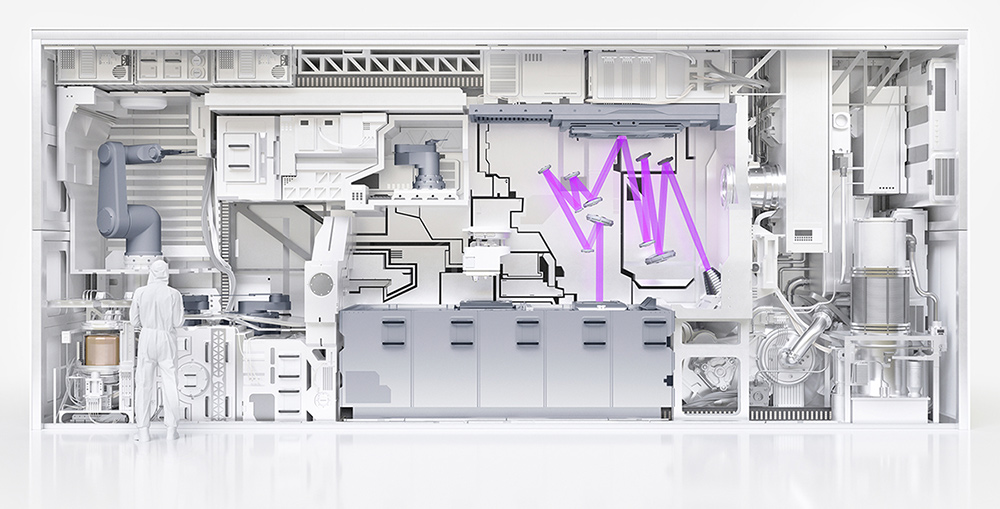

Advanced EUV lithography systems conduct multiple sophisticated handling, exposure and imaging functions, all within a high-vacuum environment that provides the high purity in semiconductors that today’s standards require.

At the heart of these systems is where you’ll find our ultraclean static round cables for Projection Object Box (POB) and Illuminator, where optical assembly takes place. Light is transmitted from reticle to wafer using a complex series of mirrors that reduce the reticle mask pattern to the size of the chip.

Features & Benefits

Designed for static applications, we manufacture GORE Ultraclean Static Round Cables and Assemblies with unique features that meet the most extreme requirements for high-vacuum environments.

- low-particulation, low-contamination, low-outgassing materials

- chemically inert and temperature-resistant materials

- very flexible round cable construction

Our finished cables and assemblies provide manufacturers with a handful of benefits unmatched by other lithography cables, like:

- meet EUV Cleanliness Grade 1 specifications for high purity

- greater precision and cleanliness to support more extreme miniaturization

- deliver higher data rates with greater signal integrity over longer distances

- tight, flexible bend radius for easy install and precise, reliable terminations

- greater reliability to support demands for higher yield and productivity

- less maintenance, downtime and cost and more EUV machine uptime

Technical Specs

These values demonstrate the electrical, mechanical and environmental performance of GORE Ultraclean Static Round Cables and Assemblies for lithography.

| Mech./Environ. Property | Value |

|---|---|

| Jacket Material | PTFE & Fluoropolymer |

| Jacket Color | White and Opaque |

| Core Types | Signal & Power |

| Minimum Bend Radius | > 10 x OD |

| Temperature Range °C | -20 to +260 a |

| Cleanliness Class (ISO14664-1) | 1 |

| Outgassing Rate mBar liter/sec cm2 | |

| H20 (AMU 18)b | 6.00E-10 |

| CxHyv (volatile CxHy) (AMU 45-100)b | 2.00E-12 |

| CxHynv (non-volatile CxHy) (AMU 101-200)b | 5.00E-13 |

| Hydrogen-Induced Outgassing (HIO) | Applicable |

| Forbidden Materials | Applicable |

| Particle-Free | Applicable |

| Certifications | UL |

a. Cable values depend on application requirements.

b. AMU = Atomic Mass Units.

Why Gore?

When it comes to lithography, you need more than just cable and assembly “products” — you need leading-edge, integrated solutions that are backed by a resourceful, capable and proven partner.

Working with us and specifying reliable Gore cables and assemblies for static and high-flex applications can help you achieve more EUV machine uptime, even when running at higher wafer/hour speeds over multi-million production cycles. We’re not just here to provide ultra-high vacuum cables — we’re here to meet ultra-high expectations as well.

Resources

Aktuellste News

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Verwandte Produkte

Cables & Cable Assemblies

Folge GORE® Ultraclean Static Round Cables and Assemblies for Lithography