GORE® PEM for Water Electrolysis

Optimizing performance and lowering costs for Proton Exchange Membrane electrolyzers — without compromising output.

Kontakt

United States

+1 410 476 2699

Germany

+49 89 4612 0

China

+86 21 5172 8299

Japan

+81 3 6746 2570

Korea

+82 2 393 3411

Overview

Green hydrogen production must scale up significantly to achieve our net-zero ambitions. However, the water electrolysis (WE) market is a challenging operational landscape.

Engineers must solve the “system dilemma” of optimizing performance, safety and durability — where strengthening one vector means compromising on the others.

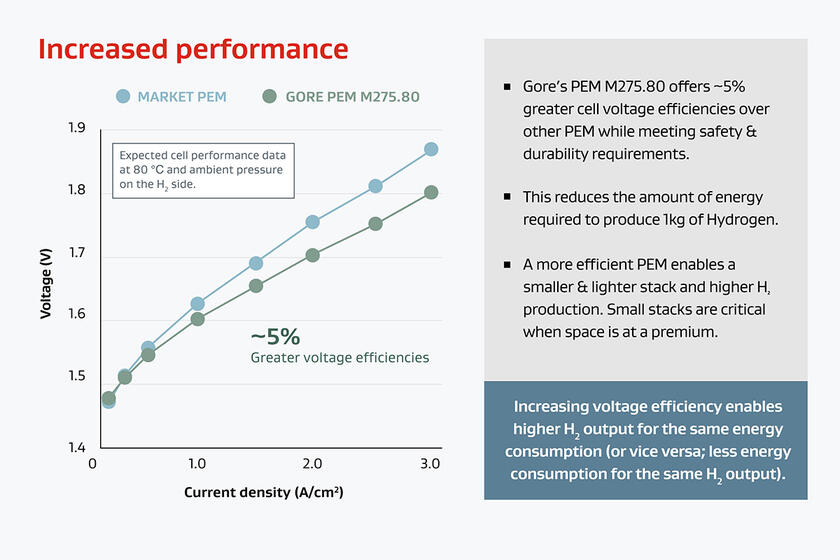

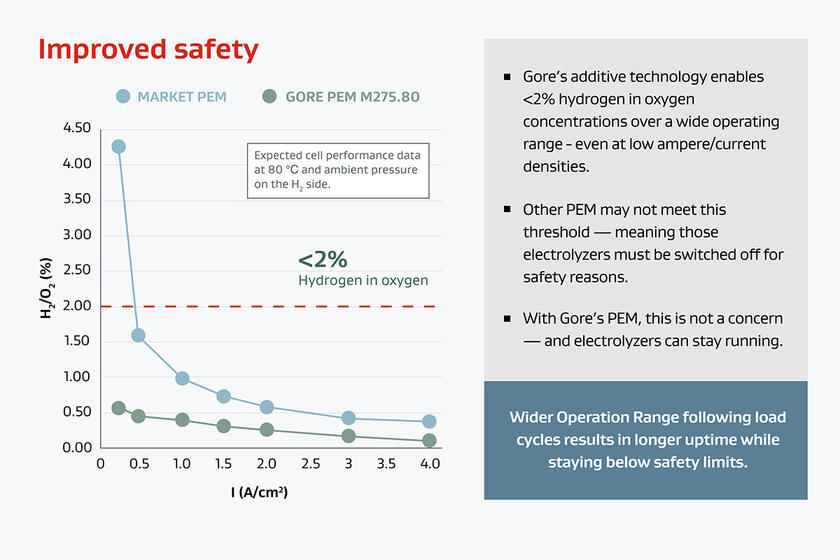

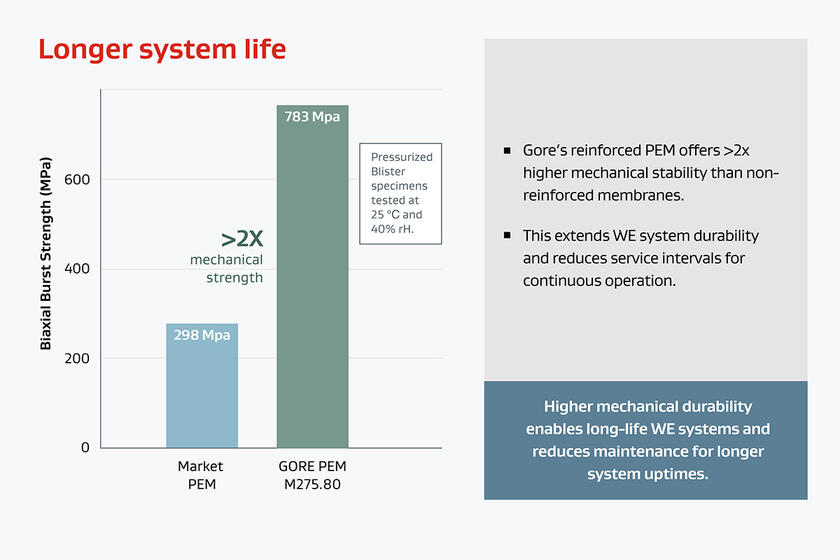

GORE® PEM for Water Electrolysis M275.80 breaks through performance barriers by optimizing all three vectors at the same time.

Our advanced membrane achieves new levels of hydrogen electrolysis efficiency and scalability, lowering the levelized cost of hydrogen (LCOH).

For almost three decades, we've led the market in producing proton exchange membranes (PEM) for fuel cells.

Today, our state-of-the art production facilities and enterprise capabilities are available immediately to support multi-gigawatt water electrolysis systems.

Product Benefits

Advantages of GORE PEM for Water Electrolysis

Water electrolysis OPEX must be reduced to achieve the LCOH necessary for large-scale WE commercialisation.

Our advanced material attributes tackle technology trade-offs, improving stack efficiency, reducing hydrogen plant operating expenses and mitigating risks in hydrogen production.

Gore: a materials science company

Our technical expertise allows us to engineer PEM to meet the individual requirements of the most demanding applications.

For PEM water electrolysis systems, we designed and developed a membrane that is both very thin and very stable — enabling effective, durable and safe hydrogen production.

| Gore’s proprietary ePTFE-reinforced layer | Unique perfluorinated ionomer | Advanced additive technology |

|---|---|---|

|  |  |

| Improving durability and performance with thin, highly conductive, mechanically durable membranes. | Enabling increased performance with high proton conductance + high voltage efficiency | Providing better durability and safety with enhanced chemical durability + reduced H2 crossover |

PEM vs other electrolysis technologies

HYDROGEN INDUSTRY INSIGHTS

From products to partnerships, there are many factors to consider between different electrolysis technologies.

Gore believes each one has an important role to play in the water electrolysis ecosystem to accelerate the clean energy transition.

Why Choose Gore?

Gore has been at the forefront of PEM technology for nearly three decades, championing every aspect of PEM production from design to development to delivery.

Our engineering expertise and global supply chain capabilities are ready to support multi-Gigawatt water electrolysis installations — immediately.

| Industry & Application Expertise

|

| Quality Assurance

|

| Production Excellence

|

| Vertical Integration

|

| Non-profit CollaborationEngaging and collaborating with key:

|

Technical Specifications

GORE PEM M275.80 Technical Data

| Physical Characteristics | |

|---|---|

| Thickness1 [µm] | 80 |

| Tensile strength1 in Machine Direction [MPa] | 55 |

| Tensile strength1 in Transverse Direction [MPa] | 55 |

| Proton resistance2 [mOhcm²] | 57 |

| H2 permeance3 [mA/cm²/MPa] | 7 |

| Roll Properties | |

|---|---|

| Standard roll widths [mm] | 320, 400, 580 |

| Length [m] | 100 |

| Orientation | Product in roll form is shipped with the membrane anode side facing outwards |

| Quality Assurance | |

|---|---|

| Product visual inspection for defects | 100% automated |

| Clean room standard ISO 14644-1 | Class 7 (Class 10,000) |

1 Measurements taken with membrane conditioned to 23 °C, 50% relative humidity (RH).

2 Proton resistance measurements taken by high frequency resistance method. Membrane impedance taken at zero imaginary impedance.

3 Hydrogen permeance measurements taken by cyclic voltammetry (CV).

Resources

Aktuellste News

Mit Freude gibt W. L. Gore & Associates bekannt, dass seine GORE-SELECT® Membran den prestigeträchtigen Projekt Award im Bereich Technologie der Toyota Motor Corporation gewonnen hat. Die GORE-SELECT® Membran wurde wegen ihrer innovativen Technologie ausgewählt, die zur Leistung und zum Wert des neuen MIRAI beiträgt. Hierbei handelt es sich um Toyotas Premium-Brennstoffzellenfahrzeug (FCEV), das im Dezember 2020 eingeführt wurde.

Pressemitteilung

W. L. Gore & Associates im Finale der PACE Awards 2020 von Automotive News

Veröffentlicht: 21. Oktober 2019

Branchenweit einzigartiges Kondensationsmanagementsystem trocknet Scheinwerfer erstmals aktiv

Pressemitteilung

Gore erhält von Sunrise Power Auszeichnung als Excellent Supplier

Veröffentlicht: 16. Januar 2019

Gore hat von Sunrise Power, einem führenden chinesischen Lieferanten von Brennstoffzellen-Stacks und -Systemen für Fahrzeuge, den Excellent Supplier Award (Auszeichnung als hervorragender Zulieferer) erhalten. Mit dem Preis wird die Fähigkeit von Gore ausgezeichnet, die strengen Anforderungen von Sunrise Power in Sachen Langlebigkeit und Zuverlässigkeit – die wichtigsten Faktoren für die Vermarktung von Brennstoffzellenfahrzeugen – zu erfüllen.

Pressemitteilung

GORE-SELECT®-Membranen lassen Brennstoffzellen-Stacks von Sunrise Power mehr als 5.000 Stunden zuverlässig laufen

Veröffentlicht: 15. Mai 2018

W. L. Gore & Associates, Inc. (Gore) wurde als Hauptzulieferer der Protonenaustauschmembran für den in Fahrzeugen verwendeten Brennstoffzellen-Stack Sunrise Power HYMOD -300 ausgewählt.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Folge GORE® PEM for Water Electrolysis